Tilt / Turn Windows

Durtherm tilt-turn windows achieve design and ventilation flexibility.

Operating with a single handle, tilt-turn windows provide two methods of operation — tilting inward, open from the top like a hopper window or turning and opening wide like a traditional in-swing casement window. Custom designed, concealed hardware delivers secure locking and is easy to use.

Click the links on the left to download product-specific details, specifications, and CAD files.

Data Sheets

Operator

Multi-latchpoint fully-concealed locking hardware controlled by single lever handle control. Horizontal and vertical perimeter locking points ensure weather-tight performance and security. In the turn mode, an adjustable friction stay holds window in any open position from 0° to 90°. In the tilt mode, the sash projects in at head approximately 10° to provide controlled ventilation without compromising security. Egress: Available as quick-release pin at sash connection.

Lever Handle

Operating hardware accepts any lever handle with 43mm attachment spacing and 7mm sq. spindle. A wide variety of styles and finishes are available from various manufacturers.

Optional Hardware

Custodial locks, sash restrictors, removable operating handle.

Large Missile Impact and Cyclical Air Pressure:

|

Passed |

1″ x 1/4″ tubular extruded frames in anodized bronze, mill finish aluminum or custom color painted aluminum. Mesh of 18 x 16 screen cloth held with vinyl spline, available in charcoal finished aluminum, mill finish aluminum, stainless steel or bright brass.

Maximum width Of screen mesh is 72″. Wood-framed screens are available.

The minimums and maximums shown are intended as guidelines. For applications that exceed these ranges, please contact the factory for assistance.

Width

Minimum: 18”

Maximum: 62″

Height

Minimum: 30”

Maximum: 96″

To ensure smooth and troublefree operation over time:

At maximum width of: 62″, limit height to: 60″

At maximum height of: 96″, limit width to: 36″

Maximum area for a single sash: 25 sq ft

Egress

Based on:

20″ clear width

24″ clear height 5.7 sq ft clear opening

Minimum unit width: 28″

Minimum unit height: 30″

To meet egress requirements:

At minimum unit width of: 28″, height must be at least: 48″

At minimum unit height of: 30″, width must be at least: 40″

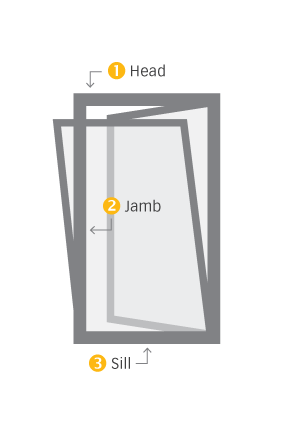

Frame Depths

Standard: 6 1/4”

Minimum*: 4 3/4”

Maximum: 10”

(*Contact factory for frame depths less than 6¼”)

Center of Glass: ASTM C-236 U-value using Viracon VE1-2M Low E glass and Lawrence Berkeley Laboratories Window 5.2 analysis program. | 1″: 0.29 with Argon: 0.24 |

Total Unit: | 1″: 0.34 with Argon: 0.30 |

| Mechanical | Results |

|---|---|

Static Air Infiltration: ASTM E283 cfm/ft2 @ 1.57 psf | Allowed 0.10 Test Result 0.005 |

Water Infiltration: ASTM E547-cyclic ASTM E331-static at 8 psf | Allowed 0.0 Test Result 0.0 |

Load Deflection: ASTM E330 10 sec at +60 and -60 psf | Passed |

Sash Torsion: AAMA/WDMA/CSA 101 / I.S.2 / A440 | Passed |

Vertical Deflection: AAMA/WDMA/CSA 101 / I.S.2 / A440 | Passed |

Forced Entry: ASTM F588 | Passed |

Double continuous extruded silicone flap gasket set in rebate around the perimeter of the sash. Engaging the multilatchpoint espagnolettes compresses the weather-strip to ensure a tight seal.

Materials

At Duratherm, you have the flexibility to choose from an extensive selection of material options. We offer a full spectrum of wood choices for both the interior and exterior, along with a variety of powder-coated aluminum clad colors for the exterior.

Glazing Configurations

All types and configurations are available to use in Duratherm windows and doors. From single monolithic to triple glazing, laminated, curved-in-place, electrochromatic switchable – virtually any type or configuration commercially available – and perhaps even some that are not.

Glazing Methods

Dry Glazing

Specially developed extruded silicone gasket sets the glass by compression. Our proprietary system is long-lived, has low maintenance, and stays water resistant.